Denim Finishing Ranges

After weaving, the Denim fabric must be chemically and mechanically treated to give it a soft and pleasant handle and correct dimensional stability, both in the warp and the weft, to prevent shrinkage in subsequent washing.

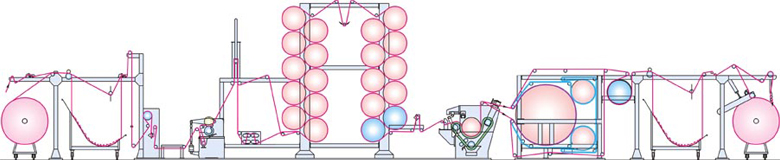

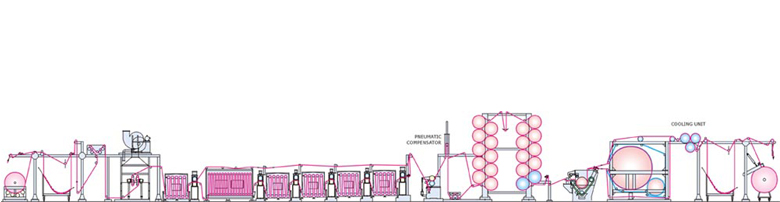

SWASTIK has recently introduced a continuous Denim De-Sizing and Finishing Range putting together a Singeing machine – Impregnator – Steamer – Washing Range – Pre-Drying and Shrinking machine to work as a continuous line.

The plant can be supplied with different preparation and dosing tanks for softeners and sensors to visualize and control the shrinkage, control fabric moisture facilitate the shrinkage of denim and obtain the best quality and productivity of the plant.

The range is normally equipped with a pneumatically operated positively driven Unwinding device with a stainless steel scray for continuous operation at the feed end and a stainless steel scray with a Big Batching and Plaiting device at the Delivery end.

Gas Singeing Machine essentially incorporates Slit type Water Cooled Burners suitable for Natural/Petrol Gas firing with possibility of penetrating or floating flame; Water cooled Rollers after the Burner; Brush Rollers positively driven by direct coupled motors with a Suction device and Exhaust for dust removal. and an impregnator with a Squeeze Nip for de-sizing chemicals.

The Steamer which follows the Impregnator is equipped with a Steam Conditioning Unit, Steam Seal at fabric entry and Water Seal at the outlet. A well insulated Steam Chest is provided to avoid water condensation. Steamer capacity 30-60-90-120 meters as may be required.

Washing Tank :

Stainless Steel Wash Tank STN-15-STN-20-STN-25, equipped with AC Invertor Drives are provided to wash the De-sized fabrics. Please refer individual catalogues for full details.

A Pre-Dryer with an adequate number of Drying Cylinders with a Heavy Squeezer and a width shrinking device follows the Washing Range. This is Followed by the Shrinking Range.